The tool produces the thermomechanical deformation and workpiece frictional heating necessary for friction stirring. INTRODUCTION Friction stir welding FSW is a solid-state joining process that uses a non-consumable tool to join two facing work pieces without melting the work piece material.

Pdf Analysis Of Tools Used In Friction Stir Welding Process

Ad Special Cutting Tools CNC Tool Grinding.

. Since there is no bulk melting of the. Friction stir welding FSW is a solid-state joining process which has emerged as an alternative technology applied in joining of high strength alloys that cannot be. In this paper cost estimation models that estimate the production cost for Metal Inert Gas MIG Friction Stir FS and Friction Stir Spot FSS welded joints are presented.

It allows metals including aluminium 2-12 lead 13 magnesium 14 steel 15 titanium 16 zinc copper 17 and metal. A friction stir welding FSW 1 5 tool is obviously a critical component to the success of the process. Friction stir processing is a modified and composite fabrication version of the FSW.

The shoulder part of the tool generates the major fraction of the frictional heat which softens. Friction stir welding and processing collectively referred to as friction stirring is not possible without the nonconsumable tool. Heat is generated by friction between the rotating tool and the work piece material which leads to a softened region near the FSW tool.

A cost model is an important tool for product design and material selection. In the proposed Phase II SBIR program QuesTek Innovations LLC will build off of the successful design framework developed in the Phase I effort to optimize scale up and commercialize a novel cermet tool material with enhanced high temperature properties to enable friction stir weld FSW processing of high melting point. Experiments regarding the influence of the FSP main parameters the tool rotational and advancing speed on material flow pattern around the tool are also considered.

Tool material should be suitable for welding of aluminium alloys 5XXX and 6XXX series sheet metal thickness in the range. The tools design diversity used for different materials even for those having high melting temperatures as steel stainless steel and Ni based alloys is presented. Friction Stir Welding and Processing.

Most important Challenges of Friction Stir Welding are application of high temperature materials Tool material selection Development of Tool Materials Tool design and Complex geometries and dissimilar materials. Oelgoetz Auto-adjustable tool for friction stir welding US. Professional Grade Products at Great Prices.

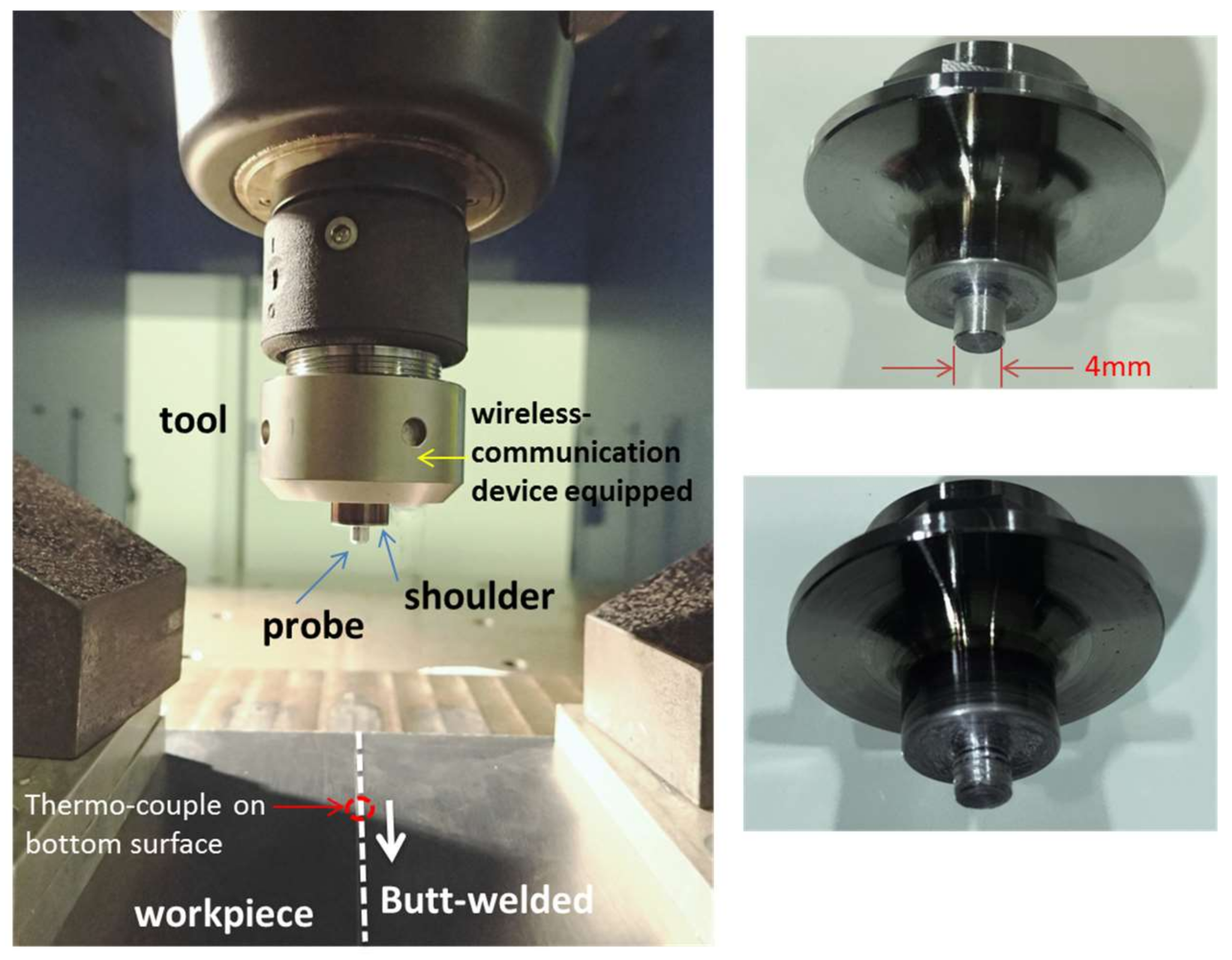

In these processes a rotating tool comprising of a pin and a shoulder mixes the materials around it. So there are two important aspects of friction stir welding tool design. An efficient and effective cost estimation tool is necessary for early design evaluation.

This article discusses materials for friction stir welding FSW pin tools various tool geometries that have been used designs for specific applications predicting and measuring tool performance and other considerations in FSW pin tool design. Ad Shop Vise Products. Material Flow Friction Stir Welding Tool Material Tool Shoulder Faying Surface These keywords were added by machine and not by the authors.

The tool typically consists of a rotating round shoulder and a threaded cylindrical pin that heats the workpiece mostly by friction and moves the softened alloy around it to form the joint. This work aims to optimize the performance evaluation characteristics such as the temperature at the weld center of the lap joint Tw the tensile shear load TSL and the hardness using an experimental design experiment for bobbin tool friction stir welding. Friction stir tooling tool materials and designs Mention a contemporary and vibrant design.

The tool materials include tool steels superalloys refractory metals carbides and ceramics and superabrasives. Friction stir tooling tool materials and designs Written By ligonis Saturday April 30 2022 Add Comment Edit Grimm et al 2015 stated friction stir welding as an alternative process for automotive batteries due to the capability of joining dissimilar materials like aluminium and copper for instance without the. All of our workholding solutions include everything you need to start using right away.

Develop new tool material for FSW friction stir welding applications. Fuller Rockwell Scientific Company. Arbegast NSF Center for Friction Stir Processing CFSP Advanced Materials Processing and Joining Center AMP South Dakota School.

However there has never been a standard FSW tool probe shoulder design that has been incorporated into standards and specifications such as BS EN ISO 25239-12011 Friction stir welding aluminium. Shop our Wide Selection Today. Tool with a narrower pin on the end is fabricated.

A friction stir welding FSW butt joint is schematically illustrated in Figure 1 in Chapter 1. Tool Materials and Designs. All pin tools are manufactured to close tolerances and undergo strict quality control to ensure.

At this point the tool begins a traverse of the weld seam deforming the material in its passage leaving behind a formed weld. Thomas Development of improved tool designs for Friction Stir Welding of Aluminum First International Conference on Friction Stir Welding June 1999. Tool material and geometry 2.

Ad Huge inventory with FREE shipping in the USA for orders over 95. Bond Technologies designs and manufactures Friction Stir Welding FSW pin tools for a variety of applications including aluminum steel and other alloys. Ad Keep Your EDM Running At Optimum Levels With Our Replacement Parts.

Friction stir welding FSW was invented by TWI in 1991 1 and substantial development has been conducted subsequently. Friction stir welding is a simple efficient and eco-friendly manufacturing technique. The tool is then inserted while rotating at a high speed into the material until the wider shoulder of the tool makes contact with the material being welded.

This process is experimental and the keywords may be updated as the learning algorithm improves. Chapter 2 Friction Stir Tooling.

![]()

Friction Stir Welding Tools Friction Stir Welding Tool Design

Pdf The Importance Of Friction Stir Welding Tool Semantic Scholar

Professional Rapid Prototyping In Shenzhen China Friction Stir Welding Aluminum Extrusion Rapid Prototyping

Metals Free Full Text Friction Stir Welding Of Non Heat Treatable High Strength Alloy 5083 O Html

301 Curtidas 5 Comentarios Instavideobr Instavideobr No Instagram Aco Ferro Iron Power Prensa Metal Metal Working Tools Homemade Tools Drill Bits

The Operational Details Of The Bobbin Friction Stir Welding Bfsw Download Scientific Diagram

Pdf The Importance Of Friction Stir Welding Tool Semantic Scholar

0 komentar

Posting Komentar